PRODUCT

We offers a wide range of pump control panel & pump control accessories for the pump control and protection market.

Product Details

Main features

- Dynamic LCD displaying pump running state

- Protect the pump against many faults

- Memory Function when Power Off&Power Recovery

- Visual &Audio Alarm For Fault Prompt

- Push Button Calibration

- Reserved space for installing internal start capacitor

- IP54 protection grade

Technical parameter

| Main technical data | |

| Rated output power | refer to the nameplate |

| Rated input voltage | refer to the nameplate |

| Trip response time of over load | 5sec-5min |

| Trip response time of short circuit | ≤0.1sec |

| Trip response time of under/over voltage | ≤5sec |

| Trip response time of dry run | 6sec |

| Recovery time of over load | 30min |

| Recovery time of under/over voltage | 5min |

| Recovery time of dry run | 30min |

| Trip voltage of over voltage | 115% of the rated input voltage |

| Trip voltage of under voltage | 80% of the rated input voltage |

| Liquid level transfer distance | ≤20m |

| Protection function |

Dry run Over load Under voltage Over voltage Pump stalled Short circuit |

| Main installation data | |

| Working temperature | -25℃--+55℃ |

| Working humidity | 20% - 90%RH, no drips concreted |

| Degree of protection | IP54 |

| Install position | Wall mounting |

| Unit dimensions(LxWxH) | 152×125×70mm |

| Unit weight (net) | 380g |

Trouble shooting guide

|

Fault Message |

Possible Cause |

Solutions |

|

flashing of

|

the real running voltage is lower than the calibrated voltage, pump is in under voltage protection state | report low line voltage to the powersupply company |

| product will attempt to restart the pump every 5minutes until line voltage is restored to normal | ||

|

flashing of

|

the real running voltage is higher than the calibrated voltage, pump is in over voltage protection state |

report highline voltage to the power supply company |

| product will attempt to restart the pump every 5minutes until line voltage is restored to normal | ||

|

flashing of

|

the real running ampere is higher than the calibrated running ampere, pump is in over load protection state | product will attempt to restart the pump every 30minutes until running ampere is restored to normal |

| pump impeller is jammed / pump motor dragging / pump bearing broken |

check pump impeller or bearing |

|

|

flashing of

|

parameter calibration not completed |

refer to parameter calibration setting |

|

flashing of

|

liquid level in the well / sump is below the pump intake, pump stops running | product will attempt to restart the pump every 30minutes until liquid level above the pump intake |

|

flashing of

|

pump motor running ampere increasing was greater than the normal running ampere (calibrated ampere) by more than 200% | cut off power supply & repair or replace pump immediately |

Installation

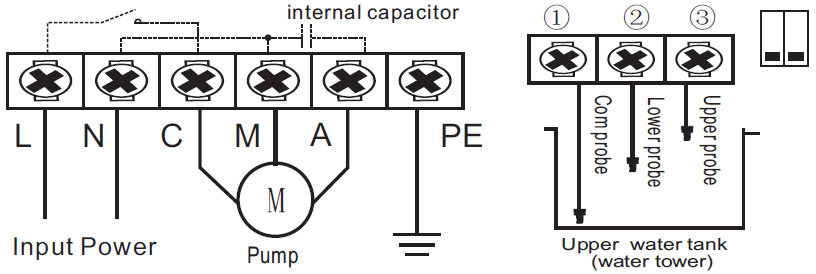

Electrical connection to the power supply line and electrical pump

- Before carrying out any installation or maintenance operation, the product should be disconnected from the power supply and one should wait at least 2 minutes before opening the appliance.

- Never connect AC power to output C/M/A terminals.

- Don't put wire, metal bar filaments etc into the controller.

- Ensure the motor, controller and power specifications matching.

- The electrical and hydraulic connections must be carried out by competent, skilled, qualified personnel.

Previous

Next

Previous

Next

Consult Now

If you are interested in our products, please leave your email and we will contact you as soon as possible. Thank you!