PRODUCT

We offers a wide range of pump control panel & pump control accessories for the pump control and protection market.

Oscar M7

Single phase deep well pump/submersible pump/ sewage pump/pipeline booster pump/multistage pump/centrifugal pump.

Category:

keyword:

Clamp

Product Details

Application scope

Single phase deep well pump/submersible pump/ sewage pump/pipeline booster pump/multistage pump/centrifugal pump.

Main features

1) Manual model have below functions: stalled, over current,dry run,lack voltage,over voltage protection.With power failure memory function

2) Especially suitable for areas with frequent power outages and non-manual duty occasions.

3) That is, before the power outage, if it is in the running state, it will automatically return to the running state if the power is turned on again.

4) If the machine is under stalled condition before the power failure, the machine will no longer run when the power is turned on again.

Technology data

- Rated output power: power sticker for your reference

- Rated working voltage: AC220V (other voltages can be customized)

- Dry run protection: running current smaller than 70% of the rated current

- Dry run protect reaction time:6 seconds.

- Dry run recovery time:15 Mins

- Over current protection: running current bigger than 130% of the rated current

- Over current recovery time:5 Mins

- Over current function time: 5 seconds to 5 Mins

- Stalled protection: Running current bigger than 170% of the rated current

- Stalled function time: less than 2 second

- Reset way: Manually cut off the power

- Protection class:IP55

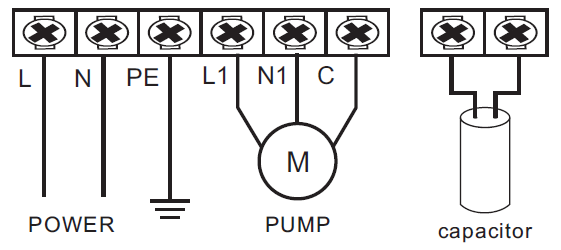

Installation wiring

After installation, please connect according to the corresponding wiring diagram.

【Water pump built-in capacitor wiring method】

【Capacitor installed inside the protector 】

Warnings

Please install and use correctly in strict accordance with the instructions. The company will not be responsible for any property damage if the following conditions occur, resulting in any failure or loss and legal liability.

1. Self-assembled and modified controllers.

2. The controller fails or is damaged due to bad weather such as thunderstorm.

3. Use a generator as the input power source.

4. When the controller shuts down with protective action, forced operation without manual troubleshooting.

5. The power failure causes the controller to fail to work normally

In order to better protect personal and equipment safety, please read the following carefully

1. The controller does not have leakage protection function.

2. The controller must be installed away from the inverter.

3. The liquid level detection cable cannot be routed through a metal pipe, and cannot be routed through the same pipe as a strong current cable. At the same time, the distance between strong and weak current wiring is not less than 30cm.

Due to unlicensed operation or non-standard construction, install the controller not according to the requirements of the company's product manual, resulting in the controller can not work normally, our company will not be responsible for any loss and does not bear any legal liability and economic costs

Consult Now

If you are interested in our products, please leave your email and we will contact you as soon as possible. Thank you!