PRODUCT

We offers a wide range of pump control panel & pump control accessories for the pump control and protection market.

ZD900

During acceleration, deceleration or steady running, detect automatically the current and voltage of motor stator, and control it within bounds based on unique algorithm, minimize fault-trip chanc

Category:

keyword:

Clamp

Product Details

- Product Selection Table

- Structure and Installation Dimensions

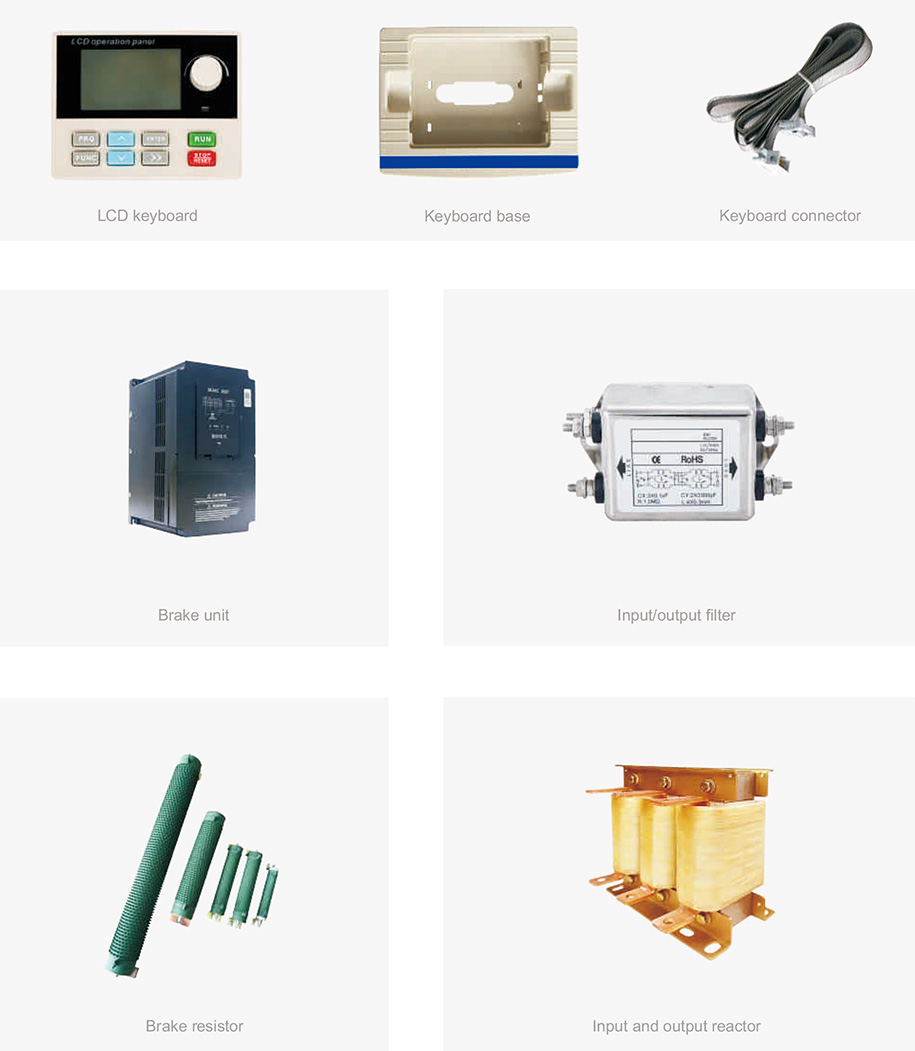

- Optional Accessories

- Operating Parameters

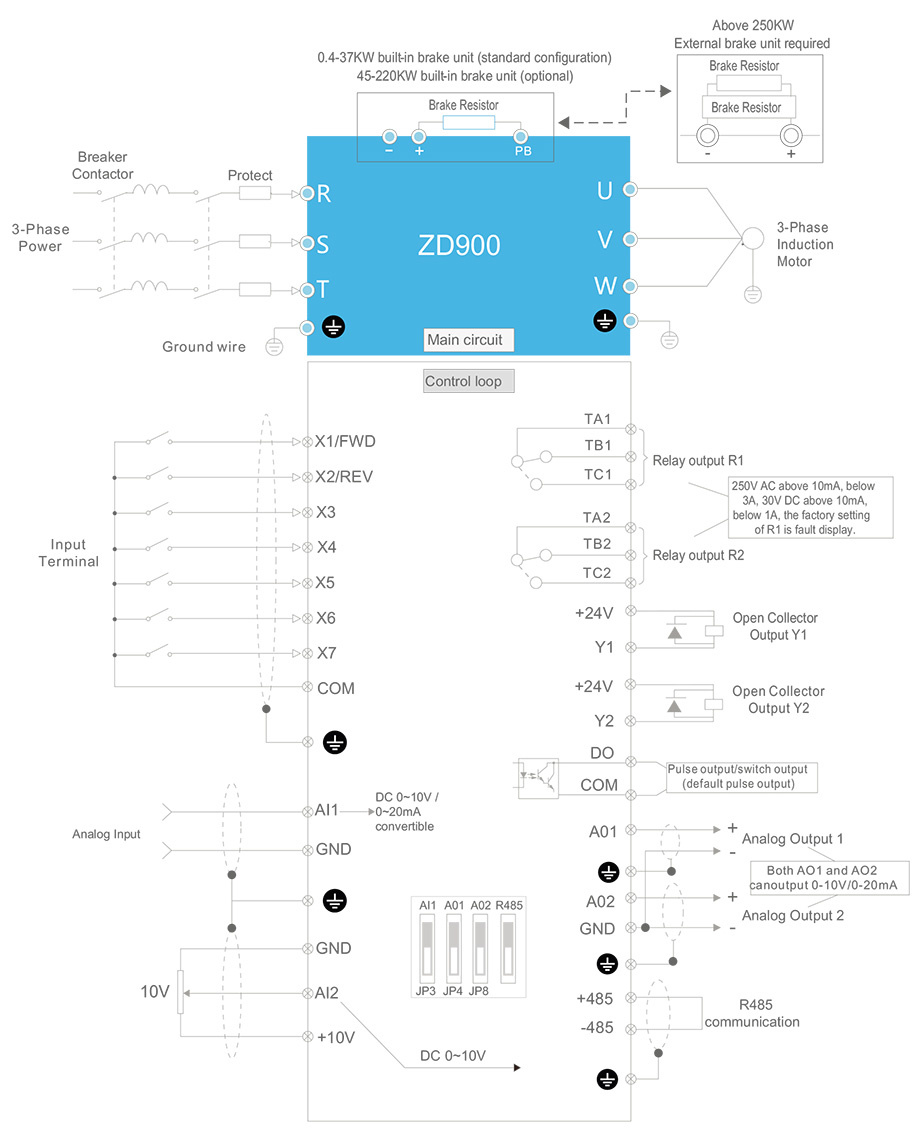

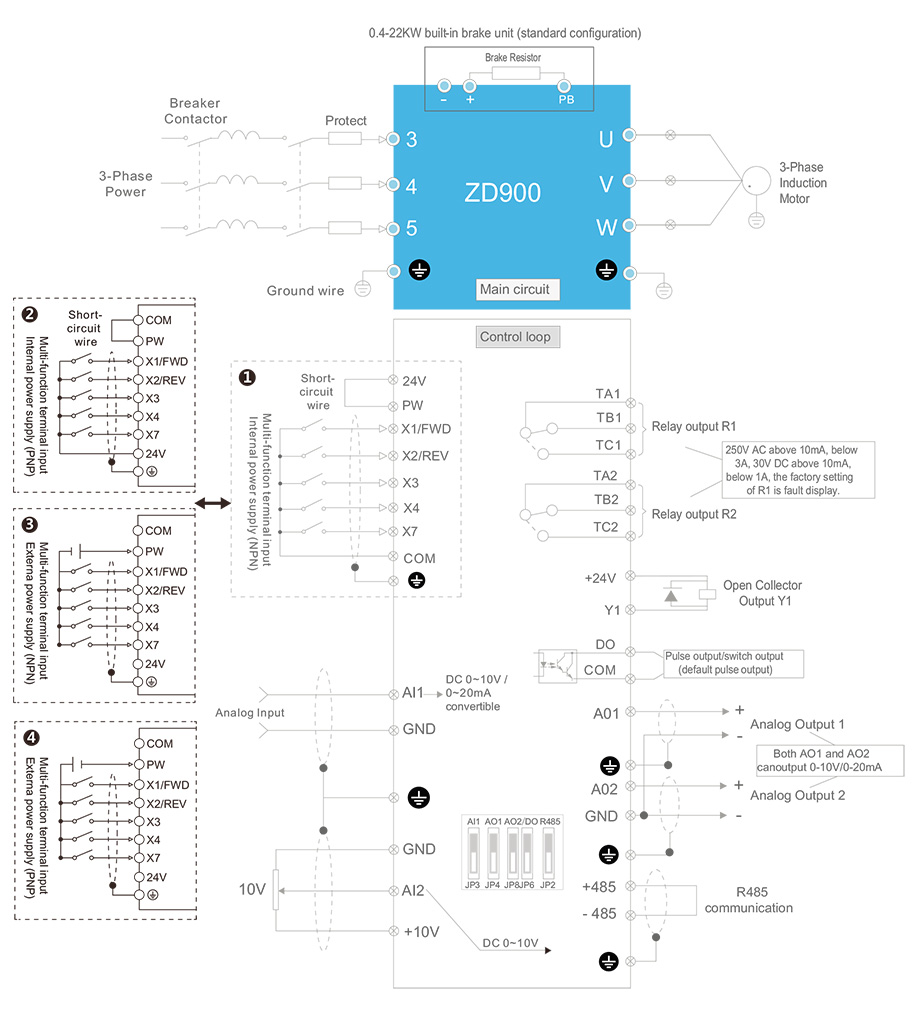

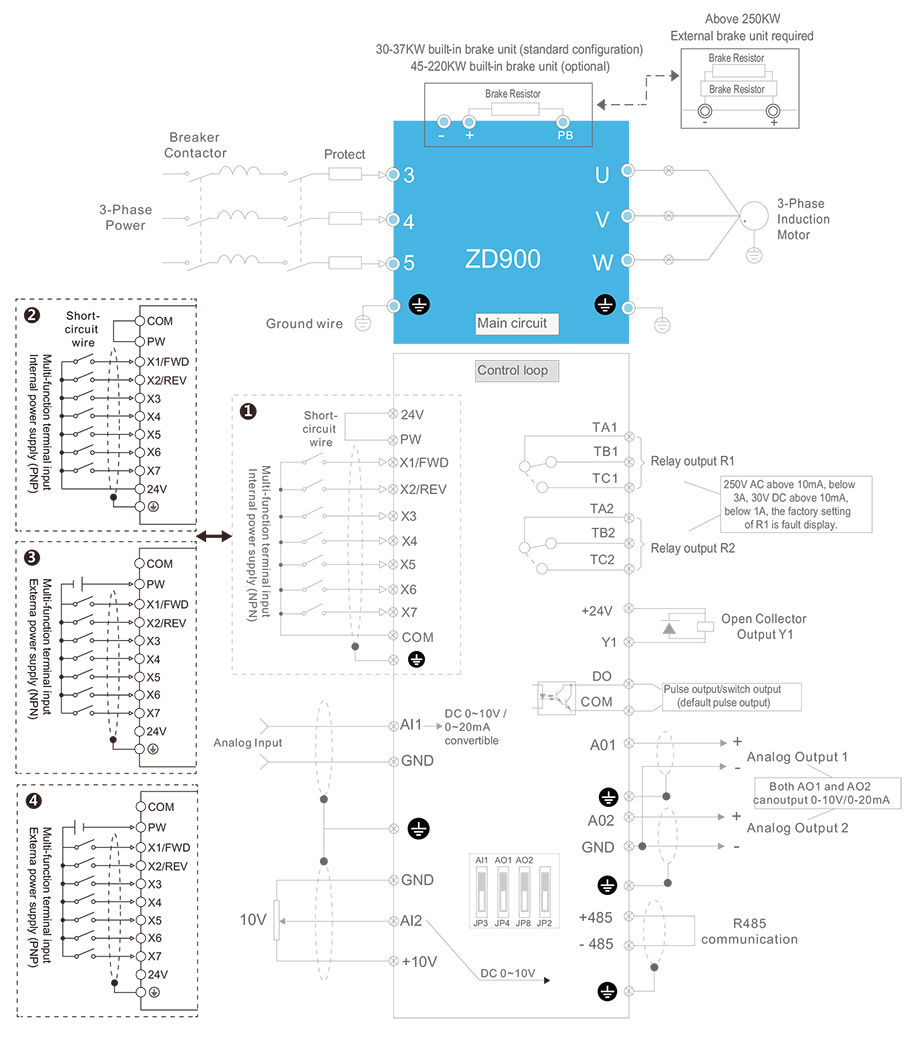

- Wiring Diagram

-

- Commodity name: ZD900

During acceleration, deceleration or steady running, detect automatically the current and voltage of motor stator, and control it within bounds based on unique algorithm, minimize fault-trip chanc

Naming Rules

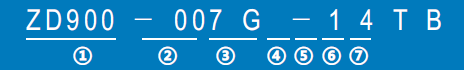

① Product series ZD900 (Inverter series) ② Model power 00A:0.4KW~1500:1500KW ③ Load type G:Constant torque ④ Output 1:3-phase 2:1-phase ⑤ Voltage level 1:110V 2:220V 4:380V ⑥ Input S:1-phase T:3-phase ⑦ Cooling mode B:Air cooling (with built-in brake unit) F:Air cooling(No built-in brake unit) Technical Index and Specification

Specification model Rated Power (KW) Rated output current (A) 1-phase 220V 50/60Hz ZD900-00AG-12SB 0.4 2.4 ZD900-00BG-12SB 0.75 4.5 ZD900-001G-12SB 1.5 7 ZD900-002G-12SB 2.2 10 ZD900-004G-12SB 3.7 16 ZD900-005G-12SB 5.5 20 ZD900-007G-12SB 7.5 30 ZD900-011G-12SB 11 42 Specification model Rated Power (KW) Rated output current (A) 3-phase 380V 50/60Hz ZD900-00BG-14TB 0.75 2.5 ZD900-001G-14TB 1.5 3.7 ZD900-002G-14TB 2.2 5 ZD900-004G-14TB 3.7 9 ZD900-005G-14TB 5.5 13 ZD900-007G-14TB 7.5 17 ZD900-011G-14TB 11 25 ZD900-015G-14TB 15 32 ZD900-018G-14TB 18.5 37 ZD900-022G-14TB 22 45 ZD900-030G-14TB 30 60 ZD900-037G-14TB 37 75 ZD900-045G-14TF 55 90 ZD900-055G-14TF 55 110 ZD900-075G-14TF 75 150 ZD900-090G-14TF 90 176 ZD900-110G-14TF 110 210 ZD900-132G-14TF 132 253 ZD900-160G-14TF 160 300 ZD900-185G-14TF 185 340 ZD900-200G-14TF 200 380 ZD900-220G-14TF 220 420 ZD900-250G-14TF 250 470 ZD900-280G-14TF 280 520 ZD900-315G-14TF 315 600 ZD900-355G-14TF 355 640 ZD900-400G-14TF 400 750 ZD900-450G-14TF 450 830 ZD900-500G-14TF 500 930 ZD900-630G-14TF 630 1150 ZD900-750G-14TF 750 1360 ZD900-800G-14TF 800 1500 ZD900-1000G-14TF 1000 2000 ZD900-1200G-14TF 1200 2400 ZD900-1500G-14TF 1500 2850 -

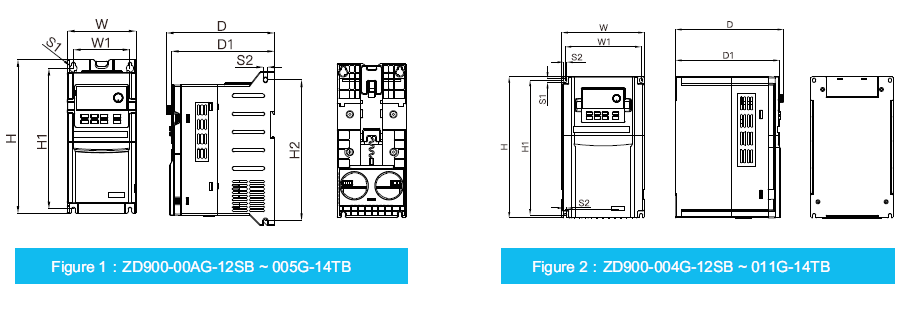

Specification model

Overall dimensions

(mm)

Installation hole position

(mm)

Installation hole diameter

(mm)

Figure

W

(mm)

H

(mm)

D

(mm)

D1

(mm)

W1

(mm)

H1

(mm)

H2

(mm)

S1

(mm)

S2

(mm)

ZD900-00AG-12SB

95

212

149

142

78

194

194

010

05

1

ZD900-00BG-12SB

ZD900-001G-12SB

ZD900-002G-12SB

ZD900-00BG-14TB

ZD900-001G-14TB

ZD900-002G-14TB

ZD900-004G-14TB

ZD900-005G-14TB

ZD900-004G-12SB

140

240

183

176

129

229

/

O6

O8

2

ZD900-005G-12SB

ZD900-007G-14TB

ZD900-011G-14TB

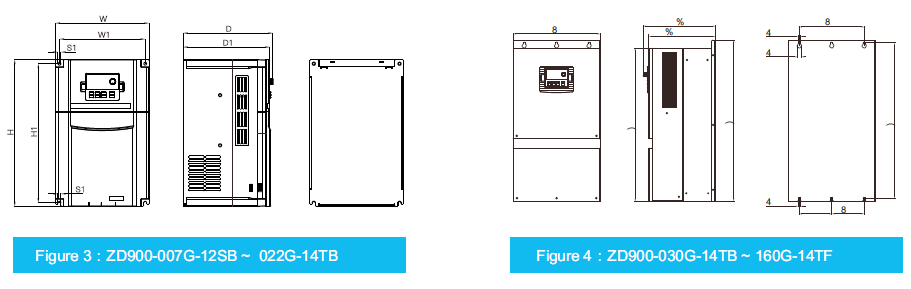

Specification model

Overall dimensions

(mm)

Installation hole position

(mm)

Installation hole diameter

(mm)

Figure

W

(mm)

H

(mm)

D

(mm)

D1

(mm)

H2

(mm)

W1

(mm)

W2

(mm)

H1

(mm)

S1

(mm)

S2

(mm)

ZD900-007G-12SB

205

322

197

190

1

188

/

305

07

1

3

ZD900-011G-12SB

ZD900-015G-14TB

ZD900-018G-14TB

ZD900-022G-14TB

ZD900-030G-14TB

270

463

223.9

206.3

437.7

201.5

/

444.5

O6.5

013.5

4

ZD900-037G-14TB

ZD900-045G-14TF

320

522

257.6

240

489

200

100

499

09

016.5

ZD900-055G-14TF

ZD900-075G-14TF

340

720

305.6

288

663

260

130

700.5

09

016.5

ZD900-090G-14TF

ZD900-110G-14TF

ZD900-132G-14TF

380

720

305.6

288

663

260

130

700.5

09

016.5

ZD900-160G-14TF

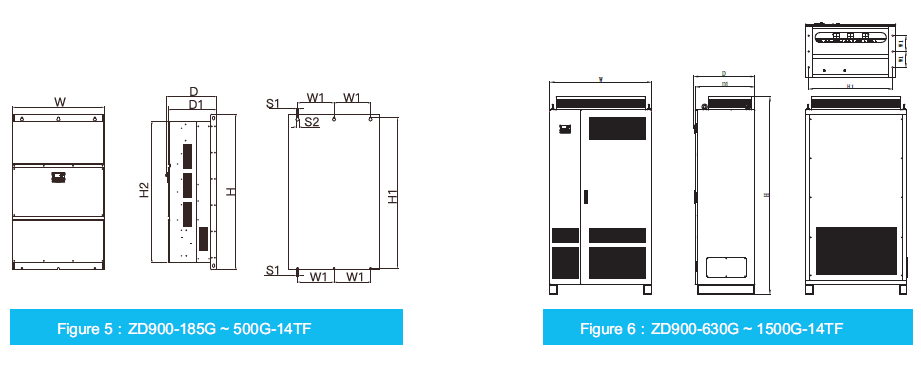

Specification model

Overall dimensions

(mm)

Installation hole position

(mm)

Installation hole diameter

(mm)

Figure

W

(mm)

H

(mm)

D

(mm)

D1

(mm)

H2

(mm)

W1

(mm)

W2

(mm)

H1

(mm)

S1

(mm)

S2

(mm)

ZD900-185G-14TF

470

830

347.1

329.5

743

343

171.5

791

011

024

5

ZD900-200G-14TF

ZD900-220G-14TF

ZD900-250G-14TF

540

1060

416.6

399

970

420

210

1031.5

013

026

ZD900-280G-14TF

ZD900-315G-14TF

ZD900-355G-14TF

650

1090

416.6

399

1000

420

210

1061.5

013

026

ZD900-400G-14TF

ZD900-450G-14TF

750

1280

416.6

399

1160

600

300

1237

013

026

ZD900-500G-14TF

ZD900-630G-14TF

1024.5

1906

620

602.5

/

180

1

954.5

018

/

6

ZD900-750G-14TF

ZD900-800G-14TF

1332

1909.5

720

702.5

/

225

1

1262

018

/

ZD900-1000G-14TF

ZD900-1200G-14TF

1732

1909.5

770

752.5

1

250

/

1662

018

1

ZD900-1500G-14TF

-

-

Functional description Specification index Input Rated Voltage, Frequency 3-phase (4T)AC 380V, 47-63Hz; 1-phase(2S)AC 220V, 47-63 Hz Allowed Voltage Range 3-phase(4T)AC 320Vj480V; 1-phase(2S)AC 160Vj260V Output Voltage 14TdOj480VG12Sd0j260V Frequency Vector control: 0~500Hz V/F control: 0~500Hz Overload Capacity 150%rated current 60s, 180%rated current 5s; 195%rated current 0.5s Control Mode V/F control, speed-sensor-less vector control(SVC) Control Character Frequency Analog Input Maximum frequency X0.025% Setting Resolution Digital Setting 0.01Hz V/F Curve(voltage frequency character) Three types: linear type; multi-point type; Nth power type V/F curve(to the power of 1.2, 1.4, 1.6, 1.8, 2) V/F Control V/F separation 2 types: full separation, half separation Torque Compensation Manual setting: 0.0~30%of rated output Automatic compensation: according to output current and motor parameter Automatic Currentlimiting and Voltage-limiting During acceleration, deceleration or steady running, detect automatically the current and voltage of motor stator, and control it within bounds based on unique algorithm, minimize fault-trip chanc Senseless Vector Control Voltage Frequency Character Adjust pressure/frequency ratio according to motor parameter and unique algorithm Torque Character Starting torque: 150%rated torque at 1.0Hz(VF control)

150%rated torque at 0.25Hz(SVC)

Running speed steady-state accuracy: ≤±0.2%of rated synchronous speed

Speed fluctuation: ≤±0.5%rated synchronous speed

Torque response: ≤20ms(SVC)

Motor Parameter Self-measurement Being able to detect parameter automatically under static state and dynamic state of motor, thus guarantee an optimum control. Current and Voltage Restrain Current closed-loop control, free from current impact, perfect restrain function of overcurrent and overvoltage Undervoltage Restrain during Running Specially for users with a low or unsteady voltage power grid: even lower than the allowable voltage range, the system can maintain the longest possible operating time based on its unique algorithm and residual energy allocation strategy Typical

Function

Multi-velocity and Traverse Operation 16 segments programmable multi-velocity control, multiple operation mode.Traverse operation: preset frequency and center frequency adjustable, parameter memory and recovery after power cut. PID Control RS485 Communication Built-in PID controller (frequency can be preset)Standard RS485 communication function Frequency

Setting ResolutionAnalog Input Direct voltage 0~10V, direct current 0~20mA (optional up limit and lower limit) Digital Input Operation panel setting, RS485 port setting, UP/DOWN terminal control, or combined with analog input Output Signal Digital Output 2-channel Y terminal open collector output and 2-channel programmable relay output-TA, TB, TC(NPN version) 1-channel Y terminal open collector output and 2-channel programmable relay output-TA, TB, TC(NPN+PNP version) Analog Output 2 channel analog signal output, output ranging within 0~20mA or 0~10V with flexibly setting, achievable output of physical quantities like set frequency, output frequency Automatic Steady voltage Operation Dynamic steady state, static steady state, and unsteady voltage for choices to obtain the steadiest operation Acceleration and Deceleration Time Setting 0.0sj65000.0s can be set continuously, S-type and linear type are optiona Brake Dynamic Braking Dynamic braking initial voltage, backlash voltage and dynamic braking continuous adjustable DC Braking Halt DC braking initial frequency: 0.00~[F00.10]Max.frequency

Braking time: 0.0~100.0s; Braking current: 0.0%~100.0%of rated current

Low Noise Running Carrier frequency 0.5kHz~16.0kHz continuous adjustable, minimize motor noise Speed Tracking and Restart Function Smooth restart during operation, instantaneous stop and restart Counter A built-in counter, facilitate system integration Operation Function Upper limit and lower limit frequency setting, frequency hopping operation, reversal running restraint, slip frequency compensation, RS485 communication, frequency control of progressive increase and decrease, failure recovery aomatically, etc. Display Operation Panel Display Running State Output frequency, output current, output voltage, motor speed, set frequency, module temperature, PID setting, feedback, analog input and output. Alarm There are 8 running parameter records include output frequency, set frequency, output current, output voltage, DC voltage, module temperature, power-on time, and running time when tripped by three-time faults. Protective Function Overcurrent, overvoltage, undervoltage, module fault, electric thermal relay, overheat, short circuit, default phase of nput and output, motor parameter adjustment abnormality, internal memory fault, etc. Environment Ambient Temperature -10℃~+40℃(please run the VFD in derated capacity when ambient temperature is 40℃~50℃) Ambient Humidity 5%~95%RH, without condensing drops Surroundings Indoors (without direct sunlight, corrosive or flammable gas, oil fog and dust) Altitude Running in derated capacity above 1000m, derate 10%for every 1000m rise. Structure Protection Level IP20 Cooling Method Air cooling with fan control Installation Method Wall-hanging type -

The wiring parts of VFD include maior loop and control loop. Open the cover of l/0 terminals, users can see the maior loop terminaand control loop terminal, and the users must clearly select the model and connect accurately according to the wiring circuitdiagrams of different models listed below.

(1)NPN version

(2)NPN+PNP version

ZD900-00AG-12SB~ZD900-022G-14TB

ZD900-030G-14TB~ZD900-1500G-14TF

Previous

Next

Related Products

undefined

Consult Now

If you are interested in our products, please leave your email and we will contact you as soon as possible. Thank you!